High speed line for producing Shoppers and Bottom Welded Bags, collected on pins. The type of production can be changed instantly by preselecting on the control monitor, without changing the equipment.

Ability to store and recall "Recipes" production, without changing any data to vary the type of production.

Film advancement by electronic system.

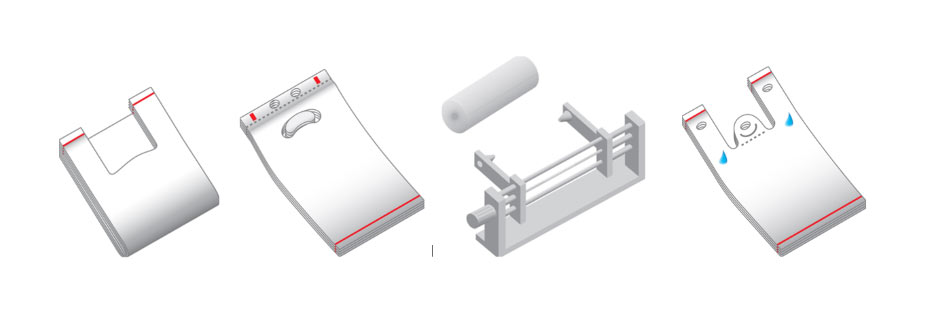

Welding machine with 3 production cycles:

Stabilized welding bar with Ni-Cr strip, closed circuit liquid cooling system. Autonomous heat exchanger, welding bar temperature of about 30 - 40° C.

Patented Mobert system for film-block using self adapting flexible pliers.

Cold cutting system with a serrated blade.

Oscillating stacking system of bags to avoid the sticking of the welding.

Exclusive Mobert system for the movement of welding unit, to allow the increase of the welding time increase even at high speed.

Punching system for Shoppers with automatic compensation of rotating plates, with device for adjusting the cutting incidence, to prevent the wear of PVC discs.

Monitor for the electronic control of working cycles, signals and instructions to eliminate the causes of stopping. Available, with optional devices, for the production of shoppers with melting point.

Group for: reel holder, cut and seal unit, gusseting unit, stacking table are available in a variety of models according to customers demands

FORMING PACKS (Patented): This device (Patented) allows to obtain pack of bags stretched out or folded in packs up to 500 pieces according to the programming on the electrical panel. In this way only one operator can pack and control the machine calmly, even for production at high speed.