Specialized line for the production of Bottom Welded Bags wound on a roll and pre-cut for tearing for working on 2 – 3 – 4 tracks.

Electronic Roller welding machine with Brushless motors running on an integrated system. Special device for handling film anti stretching welding bar designed also for very thin films. Automatic compensator and alignment device

Packing: in rolls with paper tape

Stabilized welding bar with Ni-Cr strip; Welding bar temperature of about 30 - 40 °C

Cooling with closed circuit liquid; Autonomous heat – exchanger.

Patented Mobert system for film block and raffia block using self - adapting flexible pliers

Cold pre - cutting system with ADJUSTABLE serrated blade

Production data and bag length can be digitally set on monitor with possibility to store "recipes" of production. This allows you to quickly change the type of processing, by pressing a key the previously stored data set. Automatic winding on 6 spindles for continuous operations at high production speeds

Taping unit for securing the roll with gummed tape. Conveyor belt for extracting rolls. Computerized electronic management of the whole production cycle. General controls for the main causes of Stop with instructions displayed on the monitor

Specialized equipment upon request for:

Printed Films – Automatic Insertion of Clips

Reel Holder, Cut and Seal unit, Gusseting unit are available in different versions depending on customer requirements

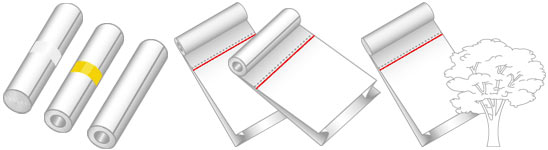

VERSION WITH and WITHOUT CARDBOARD CORE:

Independent control of each track by dancer compensator

Device for the production of rolls with cardboard core composed of: